PM-1236T 12"x36" Ultra Precision Lathe

Original price

$6,999.99

-

Original price

$6,999.99

Original price

$6,999.99

$6,999.99

-

$6,999.99

Current price

$6,999.99

- Extremely High Quality Lathe, meant for very high precision work. Perfect for the user who is looking for a high quality lathe, at a lower cost - Great for the serious hobbiest, gunsmith, or lighter industrial user (For heavier daily use, please select PM-1340GT)

- 100% Made in Taiwan

- Single Phase power available, no converters needed, or choose 3 phase if you prefer 3 phase operation

- High Precision Japanese spindle bearings, +/- .0001" Spindle Runout

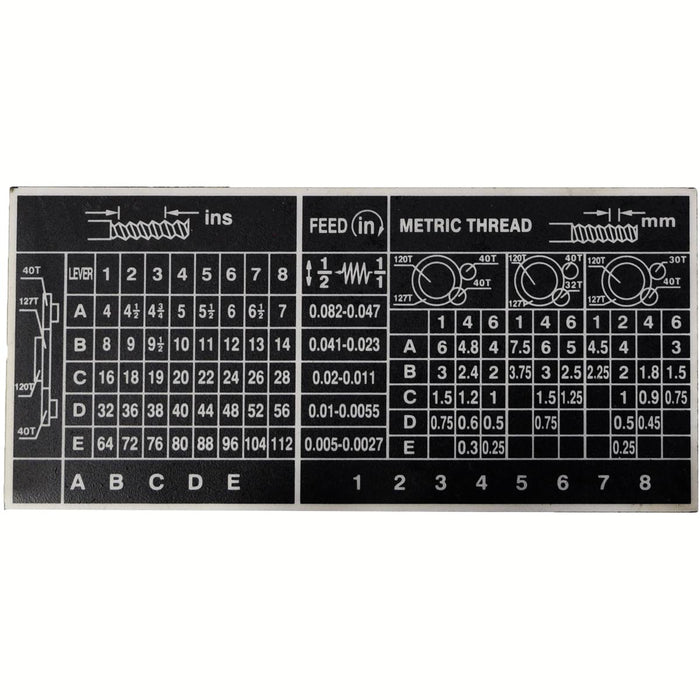

- Leadscrews Are True Inch Pitch Screws (Not Metric Conversions Like Many), a proper 8 TPI main leadscrew, cross and compound screws are 10 Threads Per Inch (.100” Per Turn)

- More Details

$399 Flat Rate Shipping in the 48 US States - Any accessories ordered with machine at the same time ship at no additional charge! (Will automatically calculate at checkout)

Availability:

In stock

Availability:

In stock