All small accessories ordered with machine ship at no extra charge!

Machine ships LTL Truck Freight at a flat rate of $399 in the 48 States. Shipments to Hawaii, Alaska, Puerto Rico, or internationally need to be quoted by our

Sales Team.

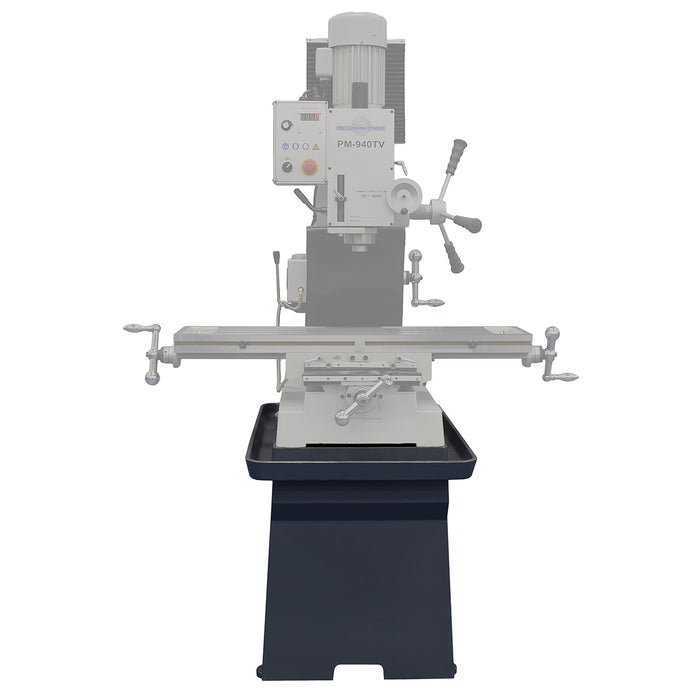

Machine ships on a pallet that is 44"x34"x53"H, stand ships on a pallet that is 48"x40".

Flat Rate Shipping

Standard Flat Rate LTL Freight Shipping services involve a 28′-48′ tractor trailer pulling up in front of your driveway and unloading your order at the curb. This is the extent of our flat rate shipping services. Carriers will NOT back their truck up your driveway, drive their truck down a dead end street, or use their liftgate to offload your machine into the bed of your pickup or trailer. Unless you have a loading dock, forklift, material handler, or other heavy equipment with forks, you will need to add Liftgate Service for $79.

Liftgate Service (Optional)

Liftgate Delivery service will get the machine from the back of the carriers truck down to the ground and up to 25' from that offloading point, provided those 25' are paved, level, and manageable by a single person with an unpowered pallet jack. If your shop/garage threshold is more than 25' from the curb end of your driveway and you don't have your own pallet jack, you will need to add Inside Delivery Service.

You MUST have a plan for how to get your machine from the curb to your shop. If you need additional delivery services, like Inside Delivery, box truck, or flatbed with forklift delivery (available in select locations), please contact us prior to your order being shipped to allow us to arrange and charge shipping accordingly. Some, but not all carriers and locations have 26′ box trucks available, but that is not guaranteed and your delivery plan should not depend on getting a box truck.

Inside Delivery Service (Optional)

The Inside Delivery option will, in appropriate situations, cause the driver to take your freight from the offloading point at the liftgate and move it into your shop or garage, as long as the route between those two points is relatively level, paved, and manageable using a standard pallet jack. This is for flat, paved driveways that are over ~30' from the curb to the threshold of your shop/garage.

Delivery Appointment

If you need the freight carrier to call you to schedule a delivery appointment

after the machine arrives at their final terminal, but

before attempting delivery of your machine, you will need to request a Delivery Appointment. This is most useful if/when you need to rent a forklift or take off work. This will add 1 day to your shipping time. Scheduling a Delivery Appointment more than 2 days from the date the freight arrives at your local terminal may incur daily storages charges that the customer will be responsible for.