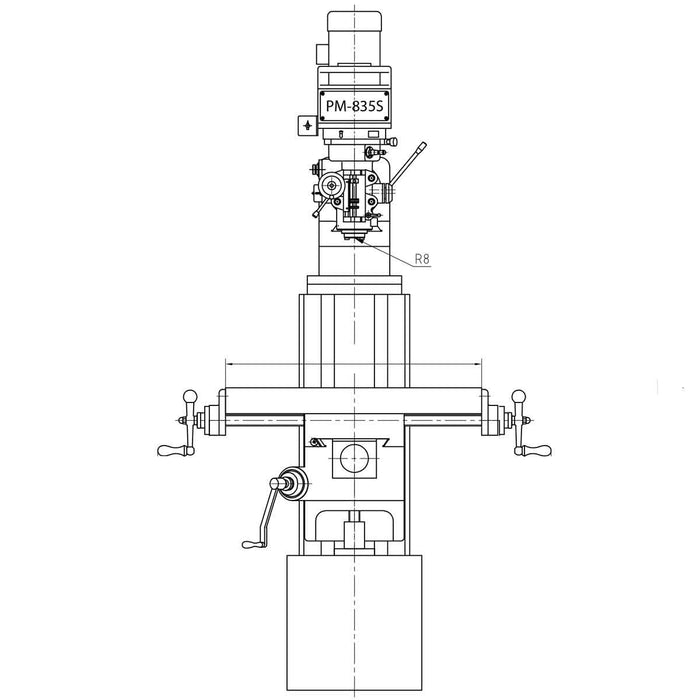

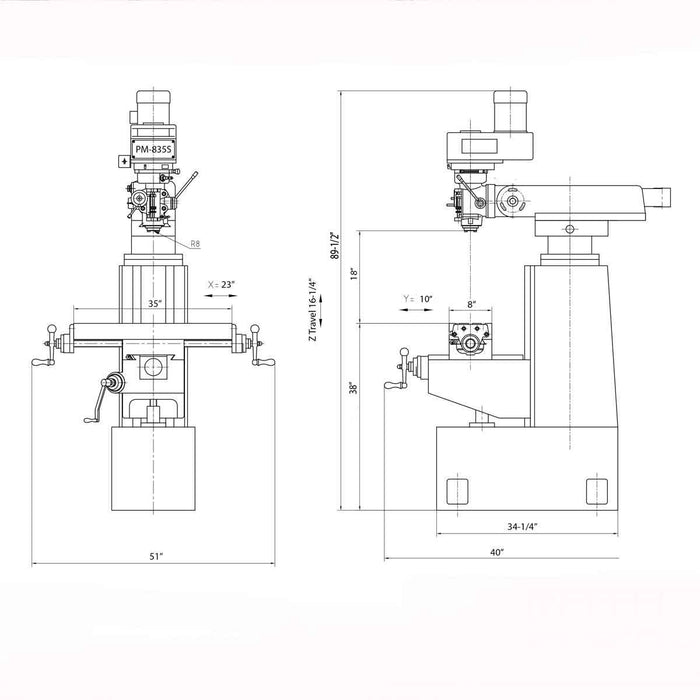

PM-835S Milling Machine

Original price

$6,999.00

-

Original price

$7,799.00

Original price

$7,799.00

$6,999.00

-

$7,799.00

Current price

$7,799.00

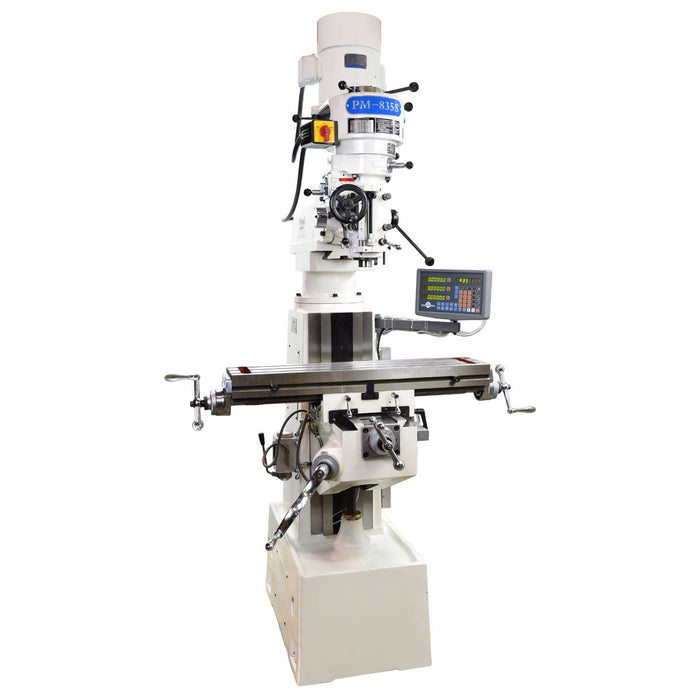

- High Grade HT250 Castings

- Head is made in Taiwan, with the body made in China, allowing for a higher quality machine, at a VERY reasonable price

- Design is exclusive to us. You will not find another machine that stacks up in features anywhere near this price range.

- FULL FEATURED milling head. Spindle down feed in 3 steps, (.0015, .003, .008 IPR), 3-3/8" diameter quill.

- Same head as used on our larger knee mills, with the cost and space savings of a smaller machine

- 5" Quill Travel

- Head Swivels Left and Right, AND Tilts Front To Back 10 degrees, only machine in this size class with this feature - Allows tramming in all directions for perfect workpiece tolerances - Excellent feature for extremely high precision work!

- COMPARE EVERYTHING WITH SIMILARLY PRICED MILLS ON THE MARKET - THEY WON'T EVEN COME CLOSE

- More Details

$599 Flat Rate Shipping in the 48 US States – Any accessories ordered with machine at the same time also ship free of charge! (Will automatically calculate at checkout)

Availability:

In stock

Availability:

In stock

Availability:

In stock

Availability:

In stock