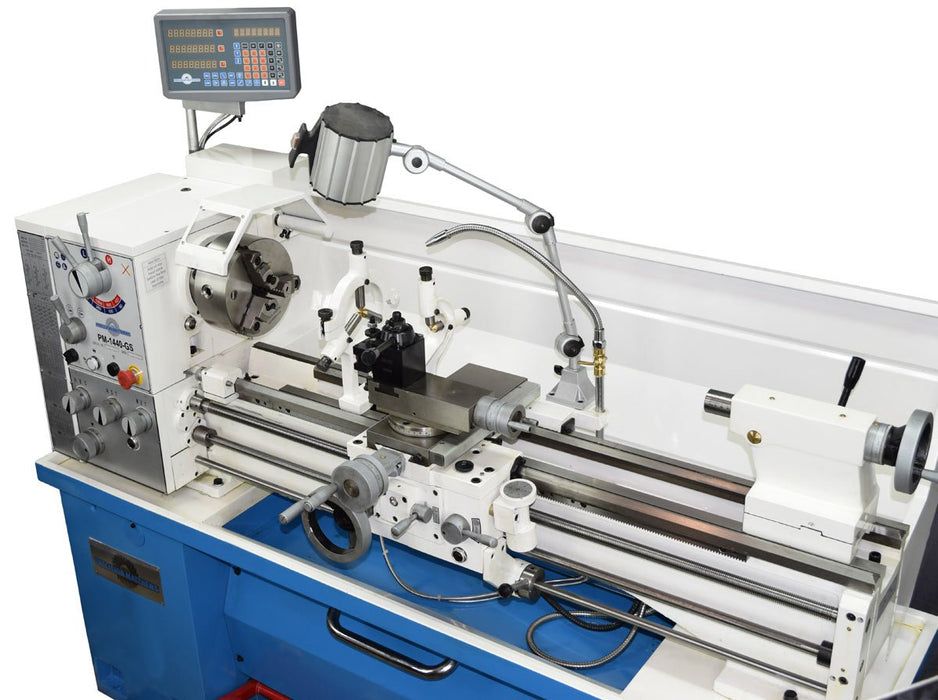

PM-1440-2SM / PM-1440-2SM-V 14"x40" Gunsmith Lathe

Original price

$8,299.00

-

Original price

$9,999.00

Original price

$8,999.00

$8,299.00

-

$9,999.00

Current price

$8,999.00

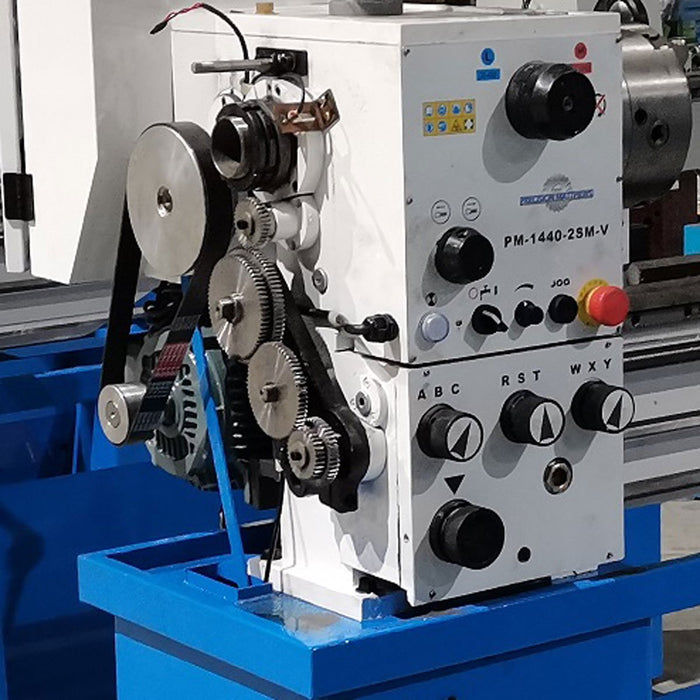

- PM-1440-2SM Model has 16 stepped speeds, 60-1800 RPM

- PM-1440-2SM-V Model is Variable Speed, 30-2000 RPM (Adjustable while running)

- Heavier duty, taller cast iron base for more solid performance

- Multi V flat drive belt setup (runs smoother than traditional V belts)

- Updated spider included for long through spindle work

- Longer 4” + compound slide travel gives extra reach when needed

- Roller and brass steady / follow rest fingers included for more versatility

- Heavier duty upgraded steady rest casting

- Updated 3 jaw chuck now with adjustable runout feature (zero set) included

- Tailstock quill dro included

- Clear chuck splash guard included

- Thicker 14 gage chip tray and back splash

- Heavy cast aluminum gear/belt cover with updated spider guard for safety

- 2” spindle bore allows through spindle work on larger diameter parts

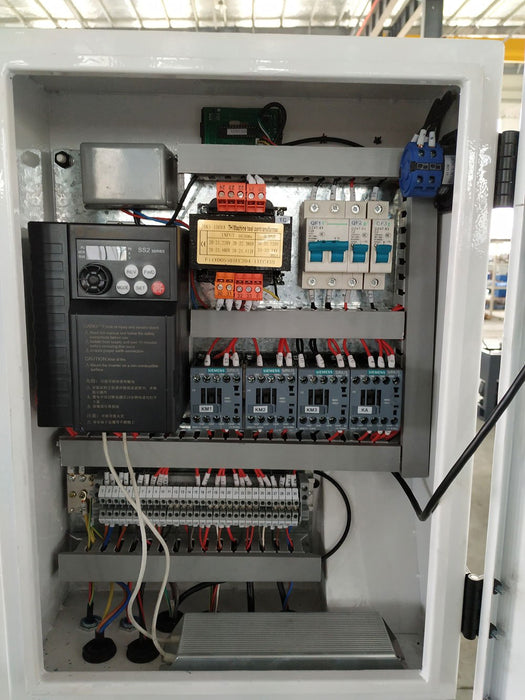

- Upgraded, higher quality motors, with dampening motor mounts isolate vibrations and allow a better finish

- Increased tailstock quill diameter for more rigid operations

- More Details

$499 Flat Rate Shipping in the 48 US States – Any accessories ordered with machine at the same time also ship free of charge! (Will automatically calculate at checkout)

Availability:

Available on Backorder

Availability:

In stock

Availability:

Available on Backorder

Availability:

In stock